Welding- and cutting technology

Offering an extensive portfolio of welding and cutting processes, we find the best solutions for you.

The selection of the best process depends on several factors, e.g. Quality and thickness of the material, visibility of the weld seam, heat sensitivity of the material, requirements for the end product or also for the speed of the welding process.

We develop a suitable solution for you based on your requirements and our expertise.

In this process, we work together with the devices and robots of the manufacturers Kuka, Fronius, Kjellberg Finsterwalde and Trumpf.

Get an insight into our technologies.

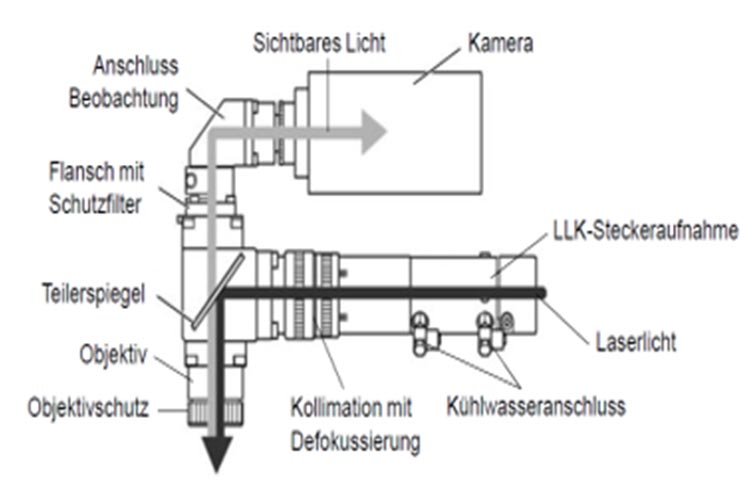

Laser welding

If fast welding speeds, slim welds and the lowest possible thermal distortion are required, laser welding is the ideal process. It is used where precise processing and high-strength connections must be achieved. Nowadays, laser welding is not only the method of choice in automotive engineering.

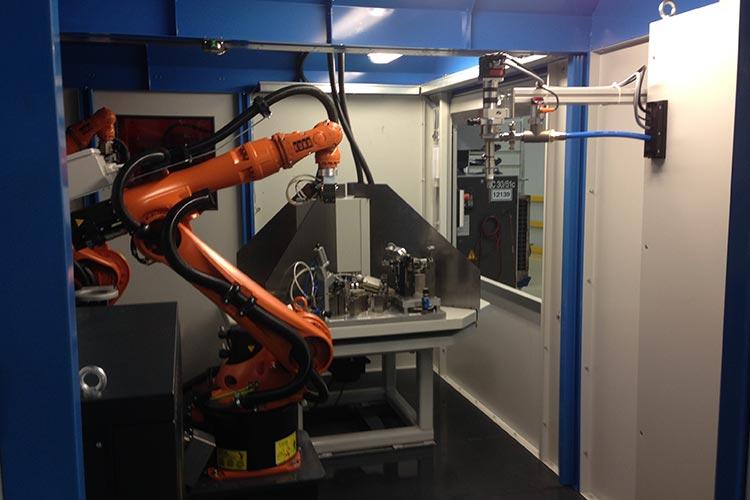

Kaslon laser-welding cabin

Example: Laser welding with Trumpf pulse laser - robot with fixed or active optics

Simulation

configuration

Trumpf pulse laser in use

Simulation

MIG/MAG welding

MIG and MAG welding are the absolute all-rounders among the welding processes. Arc welding, in which a welding wire connects the parts, is protected from external influences by a gas. Which process (gas) is used depends on your materials. Almost all materials suitable for welding can be joined together. The MAG process is used for unalloyed and alloyed steels, while we use the MIG process for high-alloy steels. The materials can be joined together from a thicknesses of 0.8 mm to over 10 mm.

TIG welding

TIG welding also belongs to the inert gas processes. It is characterized by heating the areas of the material to be welded until they liquefy and mix. The welding torch is therefore different from the MIG or MAG welding torches. Filler materials for joining can be used optionally.

This process is well suited for welding in root and constrained positions and for welding thin and medium sheet thicknesses.

TIG tool

TIG welding robot in use

TIG cell

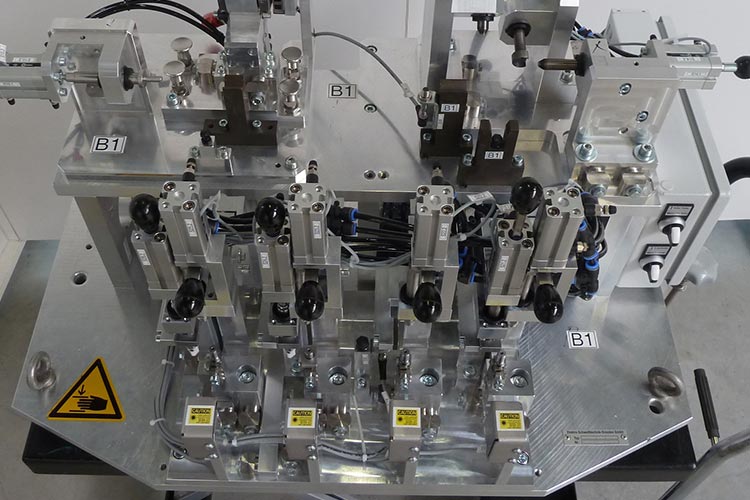

Resistance welding

Resistance welding is used for electrically conductive materials that are joined together by the heat of the electrical current flowing through the joint.

It is used wherever metal sheets are joined together without a weld seam, or a wide variety of metals and metal combinations.

Welding tool

Resistance welding

Resistance welding system

We understand your production process as a whole

Besides the welding of parts, we can also bring your metals into the right shape with our cutting processes. Therefore we use plasma and laser cutting systems from Kjellberg Finsterwalde.

Plasma cutting

An electric arc is generated between a non-melting electrode and the part during plasma cutting. The sheet receives its intensity and stability by being constricted from supplied compressed air. A highly heated, ionized gas (plasma) is produced in the torch, which transfers the arc to the part.

Plasma cutting can be used for all separation and quality cuts of electrically conductive materials. It is characterized by a high cutting speed as well as steep, burr and distortion-free cuts. It is easy to handle and simple compressed air is used as cutting gas.

This makes plasma cutting extremely economical and can be used in all areas of metal processing, such as car body construction, steel construction, refrigeration, air conditioning and ventilation construction, in the electrical, sanitary and installation sectors, and much more.

Various robot applications

The use of plasma cutting systems on robots enables high-precision and efficient machining of three-dimensional parts. Very good sensors and the freely programmable motion sequence of the robot are of advantage for cutting straight lines, contours and chamfers. Even complex cutting tasks, such as in the automotive industry, in plant and container construction or when cutting pipes, can be handled flexibly and quickly.

Kjellberg offers torches designed for robot cutting in straight design or with torch heads angled up to 90°.

We at Kaslon develop the best solution for you!

We also offer the inverters of the CUTi series from Kjellberg for handy and mobile use. They are suitable for manual cutting from 1 to 50 mm. Air as plasma gas can be used to cut mild steel, stainless steel, aluminium, brass, copper and other electrically conductive materials. Equipped with air-cooled torches, bevel cutting and plasma joints are also possible with a wide range of accessories.

Laser cutting

During laser cutting, the material of your part is removed by the laser beam heat. Laser cutting is particularly well suited for making complex cuts precisely, even with thin materials. Parts can be manufactured from a wide variety of materials with a high degree of component accuracy. The precise cutting edges and small holes ensure high accuracy. Laser cutting is also characterized by good automation capability, which makes it very economical. Due to the low heat input, there is hardly any distortion of the parts, so that this process is the method of choice for particularly precise modelling.

Just tell us what shape your part should take and we will find the right laser cutting system for you.

We will help you

What is your challenge?

Just contact us and find out which special solution we can develop for you.