Special machine construction and robotics

We develop a suitable automated welding system for your production.

We advise, plan, construct, manufacture and program your system according to your needs.

Therefore, we work with well-known manufacturers such as KUKA, Trumpf, Kjellberg Finsterwalde and Fronius. This ensures the highest quality as well as the most modern technologies for our systems.

We reliably continue service after production. We commission your system quickly and professionally on your premises and integrate it into your production.

Maintenance, optimization, spare parts supply and reparation of welding machines are also part of our service. This includes as well switchgear construction for the systems manufactured by us. According to your requirements we offer modern and automated robot solutions from the welding machine to the welding robot cell and the entire production line.

And the most important thing: with us you get everything from one source! You always have one contact person.

Our current applications present the various possibilities that you can take advantage of

with our help.

Our current application:

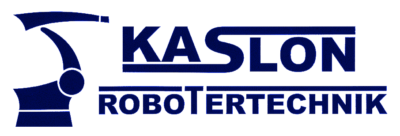

Fully automated spot welding system with intelligent welding control IQR

Spot welding is a popular process in sheet metal processing and is used for example in car body and vehicle construction. It is important to align the parts precisely and to ensure the perfect joint.

Our fully automatic system ensures maximum precision and safety. Of course, it is also equipped with the intelligent IQR welding controller, which measures the course of the weld in real time and thus enables a direct reaction to changes in the process. For a secure and stable production process.

Our current application:

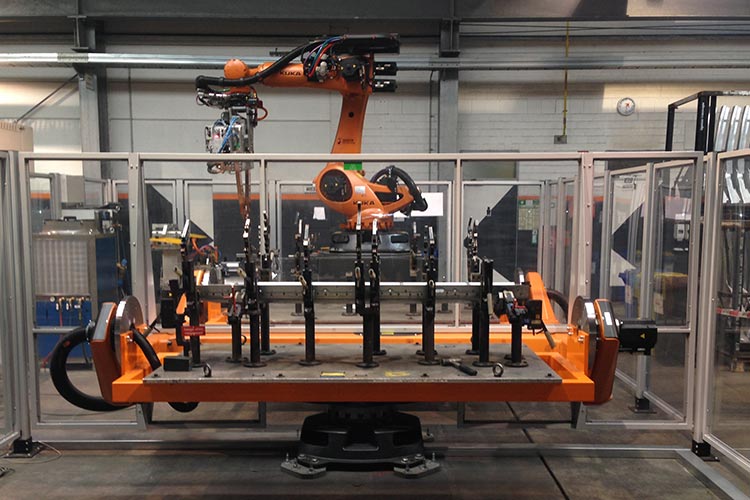

Welding of pipe bends with laser guided seam alignment

Welding of pipe bends requires highest precision and a welding process that is as distortion-free as possible. Therefore, our welding robot is supported by an optical laser that monitors the seam contour. This allows the welding unit to adapt to changes in the course of the seam and the advantages of laser welding also come into play for the welding of pipe bends.

Our current application:

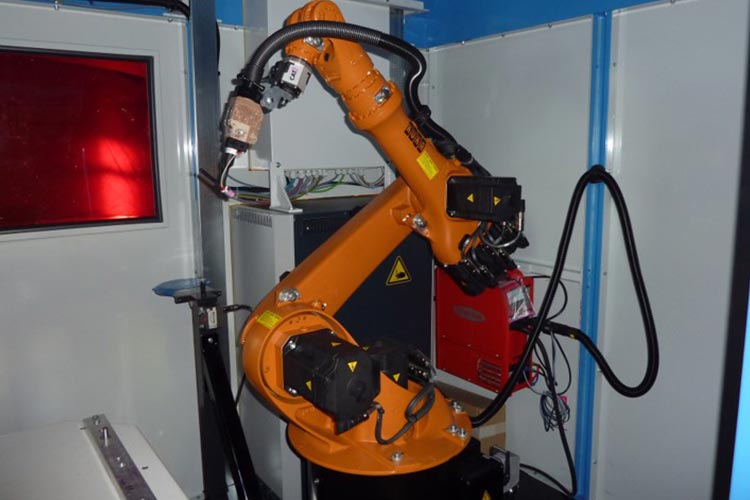

Welding and pasting in compact cells

Do you expect changes in your production process or in the structure of your production? Then our compact welding cells are the right choice for you. These cells contain the individually planned and manufactured welding and paste systems for you. If, for example, the spatial distribution of the production steps in your production changes, you can easily transport these cells with your entire welding system. For example with a forklift or an indoor crane.

Our systems in your production

Whatever you require, we develop and supply the suitable paste cutting and/or welding cell

directly into your production.

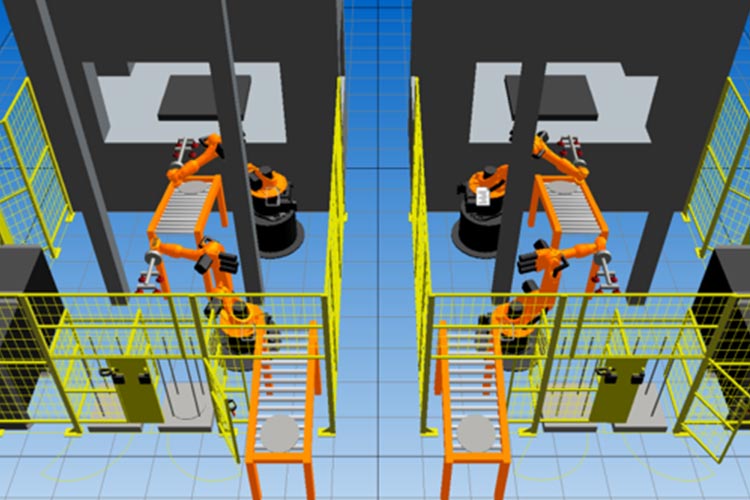

From the idea to the completed system

Planning, visualization, simulation, construction and commissioning of various systems:

Container welding machine with multifunctional application

Shuttle tables, automatic turners, planetary drives

Press equipment with robots

In simulation

Under construction

We accompany you through all process steps until the completed system is in operation in your production - and beyond.

We will help you

What is your challenge?

Just contact us and find out which individual solution we can develop for you.